Polyamides

Polyamides are the most used thermoplastics in the mechanical field. They have great mechanical properties and great resistance to abrasion, characteristics that remain intact even at high temperatures. They have a low friction coefficient and good anti-vibration properties. In addition to these characteristics, they can resist to many chemical agents, including oils, greases and common solvents. We can provide round bars, hollow bars and sheets.

Polyamides include:

- PA6

- PA6+MOS2

- PA6.6

- PA6.6+FV30%

- PA6-G

- PA6-G+OIL

- PA6-G+MOS2

Visit our Plastic Materials Website (Italian version only)

Acetalic Resin

It is a largely used material, known for its mechanical and machining properties and dimensional stability – even in humid environments. Acetalic resin is ideal when you need a physiologically inert product (food industry) with a great resistance to many chemical and solvent substances and that does not absorb water. In our warehouse we always have white, black and blue bars with standard length of 1000, 2000, 3000 mm. Our acetalic resin sheets are 1000 x 2000 mm, with standard thicknesses. It is also possible to cut flat bars of any dimension from sheets.

Visit our Plastic Materials Website (Italian version only)

PET or Arnite

It is a semi-crystalline product, ideal for the production of components with high dimensional and stability precision, even in humid environments. It is particularly suitable when high mechanical properties are required, combined with a good resistance to use and a good ease of movement – it has a low friction coefficient. PET has good electrical insulation properties and a great resistance to acids – more than polyamides and acetalic resin. We provide white or black round bars with standard length of 1000 or 3000 mm. We also have sheet in the following dimensions: 1000 x 2000 mm, 600 x 2000 mm with standard thicknesses.

Visit our Plastic Materials Website (Italian version only)

PET + P.T.F.E.

It has the same characteristics as arnite, but with the addition of P.T.F.E. powder, a solid lubricant which increases the friction coefficient and makes the material more resistant to wear loads. It is used to produce highly-stimulated components, which require a high dimensional stability – such as precision mechanism or insulation components for the electronic and electrical industry. PET + P.T.F.E. is insensitive to environmental humidity, it has a low friction coefficient but a great resistance to use. This material is available upon request, in round bars and sheets.

Visit our Plastic Materials Website (Italian version only)

P.T.F.E.

It is a fluorine-polymer with unique characteristics because it has a low friction coefficient, great resistance to external agents and a high non-stick property. It can resist to very low and high temperatures (from -200 °C to +260 °C). Under a thermal point of view, it is the most stable plastic material – as a matter of fact, any structural decompositions are noticed up to +260 °C. To increase the excellent characteristics of this material, P.T.F.E. can be combined with different elements, such as glass, bronze, graphite, coal, bisulfide. We can provide white round bars, 1000 mm or 2000 mm long – upon request we can also order extruded or molded hollow bars.

We also have sheets with the following dimensions: 600 x 600 mm, 1200 x 1200 mm, 1000 x 2000 mm, 1500 x 1500 mm.

Visit our Plastic Materials Website (Italian version only)

Peek

This is a thermoplastic material, technologically advanced, with great mechanical properties and a great chemical resistance. It can be used up to 260 °C, in hot water or steam, but also at low temperatures, up to -60 °C. It is a pretty expensive material that we provide only upon request. We have round bars with standard length (1000 mm or 3000 mm) and the color is beige/dun. We also have sheets (500 x 1000 mm, 1000 x 1000 mm, 500 x 2000 mm, 1000 x 2000 mm).

Visit our Plastic Materials Website (Italian version only)

PE or Polyethylene

Polyethylene is a pretty light material, and the most common in our life. Is it particularly resistant to chemical agents, water, acids, alcohol, petrol and saline solutions. It does not absorb water or other liquids, it is non-toxic and, as a consequence, is it largely used in the food industry. It is commonly used between -40 °C and +80 °C. PE can have different molecular densities, and for this reason we can find PE 300.000, PE 500.000, PE 1.000.000. we can provide sheets, plates, flat bars cut from sheets and round bars (1000 mm or 2000 mm long).

Visit our Plastic Materials Website (Italian version only)

PP or Polypropylene

Polypropylene is a thermoplastic material, more resistant and solid than PE, with high resistance to chemical agents, and it is commonly used between +5 °C and +90 °C. PP, thanks to its non-polarity property, is it extremely resistant under a chemical point of view: it keeps its resistance to strong saline or alkaline solutions and acids up to 120 °C. As opposed to techno-polymers, PP has lower mechanical properties (wear, traction, bend, pressure, etc.). We can easily provide white, black or grey RAL 7032 PP bars, with standard length of 1000 mm and 2000 mm, and also PP extruded and pressed sheets (1000 x 2000 mm).

Visit our Plastic Materials Website (Italian version only)

PVC

It is a thermoplastics material with an amorphous structure. It has high solidity and malleability, and great electrical properties. It is commonly used between -10 °C and +60 °C and it also has great chemical stability and resistance to acids. Is absorbs little to no water, it is self-extinguishing and can be welded or glued. We can provide natural, red, black and grey RAL 7011 round bars, 1000 mm or 2000 mm long. Upon request, we can provide hollow bars, square bars, flat bars and extruded hexagonal bars. We can also have extruded sheets (1000 x 2000 mm or 1500 x 3000 mm) and from sheets we can obtain any plate.

Visit our Plastic Materials Website (Italian version only)

PMMA

PMMA is a polymer also known as acrylic, and used as a substitute of glass for shock-proof components. It is a solid, clear material, with an excellent light conveyance ability and good resistance to chemical and atmospheric agents. It is also recyclable and non-harmful to the environment. Upon request, Musola Metalli can provide extruded shock-proof sheets, molted sheets, tubes and round bars both extruded and molted.

Visit our Plastic Materials Website (Italian version only)

PC or Polycarbonate

This material is largely used as a substitute of glass. Its main characteristics are: thermal insulation, high mechanical resistance to collisions, good machinability, lightness, easy to handle, good chemical and physical stability. PC can be sold in colored sheets, both whole or cut in plates of any dimensions, but with the supply of the remaining parts. Musola Metalli can provide compact PC sheets or alveolar PC sheets. The first one is the clearest one, and the second one is lighter and easier to handle.

Visit our Plastic Materials Website (Italian version only)

Rubber

Upon request, we can provide black rubber rounds, sheets and rolls. The standard hardness is 65/70 shore. Round bars can be lathed.li.

Visit our Plastic Materials Website (Italian version only)

PU or Polyurethane

Polyurethane is produced with a hardness range that goes from 60 to 90 shore, with excellent resistance to abrasion and to laceration. It has a great resistance to solvents, gasoline, mineral oils and grease. PU resists both in cold and hot environments, up to 80 °C. It resists to substantial dynamic stress and to use, and it also has good malleability and good rip resistance. We can provide round bars or molded hollow bars – the standard color is dun/brown. The standard length of rounds and hollow bars is 500 mm. We can also provide PU sheets with dimension 1020 x 3070 mm.

Visit our Plastic Materials Website (Italian version only)

Bakelite

Bakelite is a stratified material which is obtained through the combination of whole cotton fabric and thermo-hardening phenolic resins. It has great electrical insulation properties and good mechanical resistance. We provide sticks, lathed from sheets. Diameters go from 6 mm to 120 mm with a length of 1 meter. We also provide Bakelite sheets (1070 x 1070 mm and thickness from 1 mm to 50 mm).

Visit our Plastic Materials Website (Italian version only)

Types of Plastic Materials

The following list shows all the plastic materials that we can supply:

| QUALITY | PRODUCT | COLOUR |

| PA6 PA6,6 PA6,6 + GLASS FIBER 30% PA6 + MOS2 PA6 + OIL | Round bar, hollow bar, flat bar, sheet, plate, ribbon, square bar Round bar, flat bar, hollow bar, sheet Round bar, sheet Round bar, square bar, flat bar, hollow bar, sheet, plate Round bar, hollow bar, sheet | Natural, black, blue Natural Black Black Yellow |

| POM-C POMC-H | Round bar, square bar, hollow bar, flat bar, sheet Round bar, flat bar | White, black, blue White |

| PET | Round bar, flat bar, hollow bar, sheet | Natural, black |

| PET + P.T.F.E. | Round bar, flat bar, hollow bar, sheet | Natural |

| PEEK | Round bar, flat bar, sheet | Natural, black |

| POLYETHYLENE 300 POLYETHYLENE 500 POLYETHYLENE 1000 | Round bar, square bar, flat bar, sheet, plate Round bar, square bar, flat bar, sheet Round bar, square bar, hollow bar, hexagonal bar, flat bar, sheet, plate | Natural, black, green, white, blue, yellow Natural, black, blue, green, red Natural, black, green, natural, blue, yellow |

| POLYPROPYLENE | Round bar, hollow bar, sheet | Natural, grey, black |

| PVC | Round bar, flat bar, square bar, hollow bar, sheet, plate, ribbon, round tube, rectangular tube, angular profile, hexagonal bar, U profile, T profile | Natural, grey, black, red, transparent |

| P.T.F.E. P.T.F.E. + BRONZE 40% P.T.F.E. + COAL 25% P.T.F.E. + COAL AND GRAPHITE 25% P.T.F.E. + GLASS 15% OR 25% P.T.F.E. + GRAPHITE 15% | Round bar, hollow bar, sheet, ribbon Round bar, sheet Round bar Round bar, hollow bar, sheet Round bar, hollow bar, sheet Round bar, hollow bar, sheet | White, natural |

| PMMA | Round bar, square bar, sheet, round tube | White, transparent, black, red, opaline |

| POLYCARBONATE | Round bar, round tube, sheet | Transparent, opaline, smoky grey |

| POLYURETHANE | Round bar, sheet | Dun, yellow, red |

| RUBBER | Round bar, sheet | Black |

| BAKELITE | Round bar, flat bar, sheet, plate, round tube |

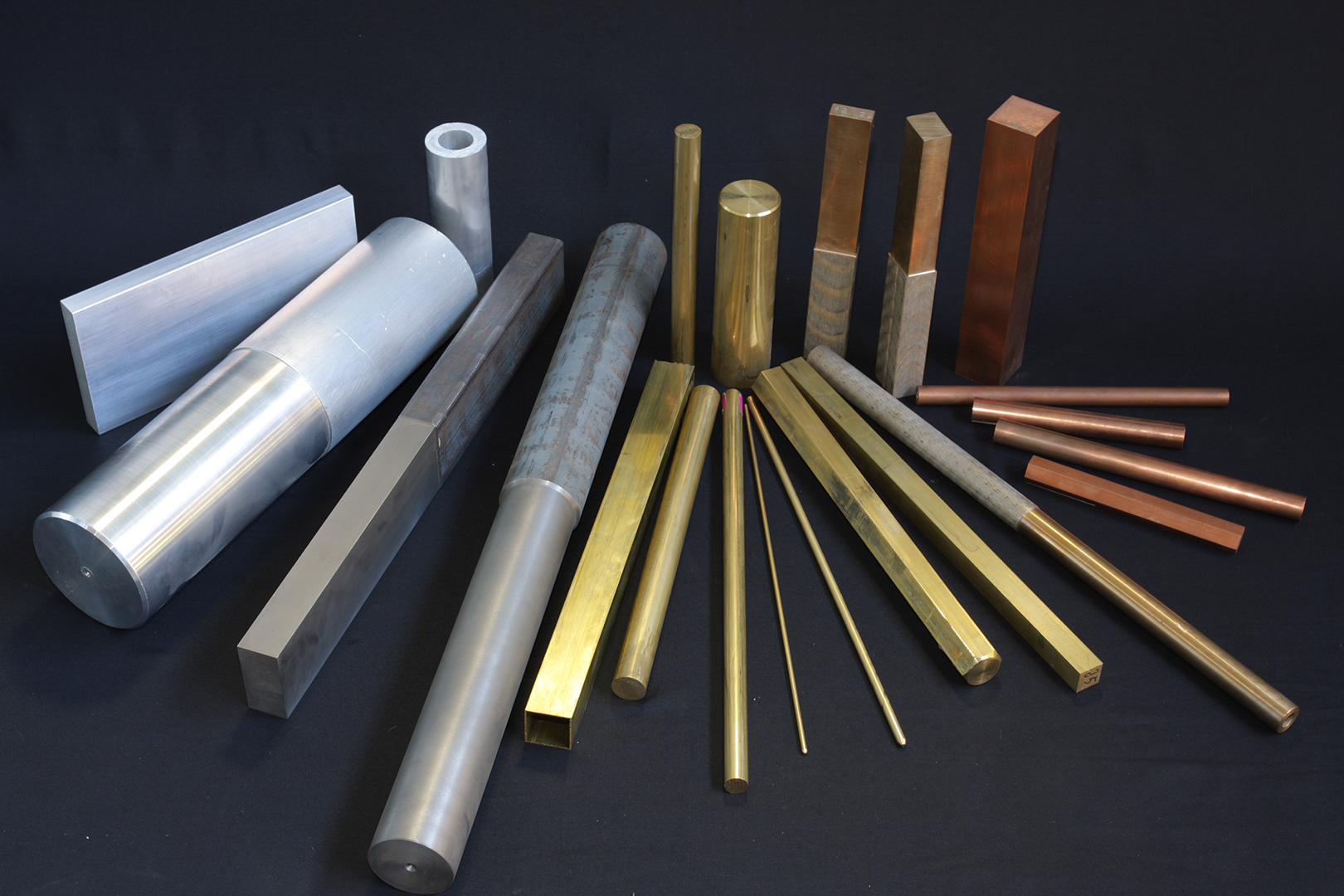

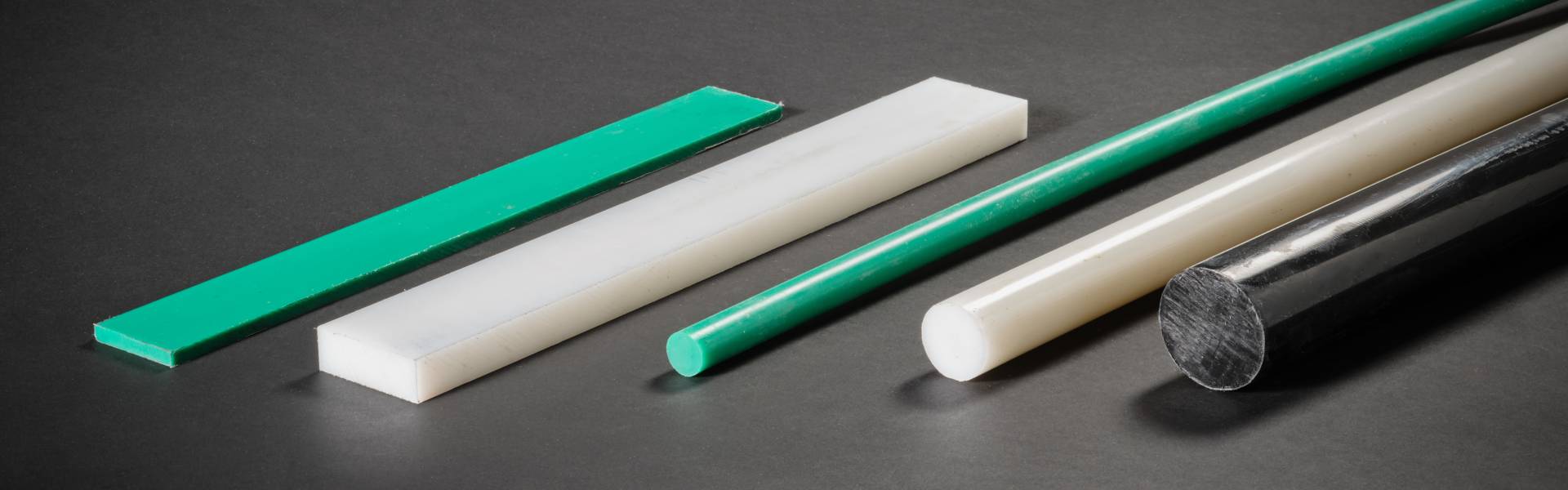

About Plastic Materials

In addition to the trade of plastic materials and non-ferrous metals, Musola Metalli knows the importance of plastic materials for the technological innovation and has expanded the range of products with thermoplastic round bars, tube and sheets. We work with important producers and suppliers, both Italian and European, in order to satisfy our clients’ requests of round bars, hollow bars, sheets, flat bars, square bars. In our warehouse we always have a wide range of dimensions and materials and we always guarantee a fast supply in case of non-availability.

There are four advantages when using plastic materials:

- Less lubrication problems

- Decrease of machining and material costs

- More resistance to collisions

- Less noisiness

Over the years, plastic materials have replaced metals in many fields of application, such as the mechanical field, the automotive field, the packaging industry, the furniture industry, the food industry, etc.

Do you need a quote or information about Plastic Materials?

Leave here your personal data, you will be contacted by our sales department.