Aluminium EN AW5083: characteristics and fields of application

Aluminium is among the most common materials that we can find in nature. It actually represents 8% of the Earth surface and is extracted from bauxite. Bauxite is also among the most abundant natural elements on our planet.

Aluminium is one of the most used materials, thanks to its mechanical and chemical properties and related advantages. The main fields of application are: engineering, aviation and space industry, packaging, etc.

Why is aluminium so versatile?

We can describe the main characteristics as follows:

- lightness and malleability: with a specific weight of 2,7 gr on cm2, is it a light metal, easy to handle. Thanks to an extremely high weight/resistance ratio, aluminium is used for the realization of light but strong and solid structures. Aluminium is very ductile and malleable, both in cold and hot machining

- corrosion resistance: resistance to water and air corrosion. Aluminium naturally has a protective oxide layer that protects it from atmospheric agents and chemical substances

- high thermal and electric conductivity: aluminium is the most suitable material for the production of electric wires and lines. It is a very good thermal conductor, so it is largely used for heating and cooling systems, mostly in household environments

- non-toxic and recyclable: all aluminium products can be recycled without losing their properties and characteristics, from thin sheets to automotive components, and from construction components to domestic tools. Aluminium is odorless and non-toxic: that’s why we can find it in kitchen tools or packaging for the food industry.

The fields of usage of aluminium are constantly changing and increasing. We normally find it in the construction industry, the transport industry (for example automotive, aerospace, railway, etc.), the electronic field and the domestic field.

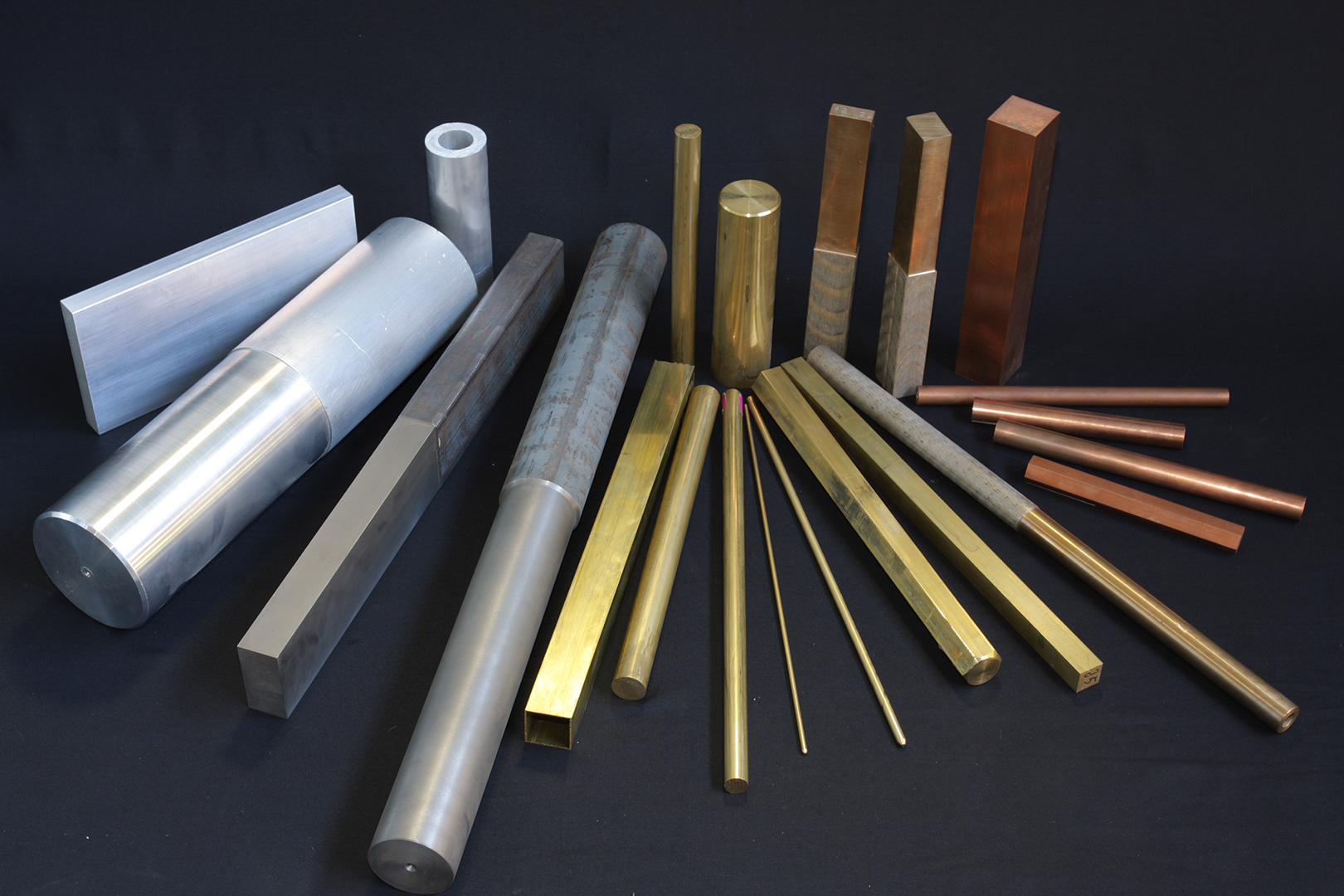

Aluminium alloys can be foundry alloys or plastic deformation alloys. The first group is appropriate for foundry flows, while the second one for semi-finished products such as bars, sheets, profiles.

Different alloying elements are added during the production of aluminium, with the aim to improve mechanical properties. Elements can be copper, silicon, magnesium, manganese, zinc, nickel.

EN AW5083: characteristics

It is an aluminium-magnesium alloy, largely used in many fields (nautical, precision mechanics, molds).

The alloy EN AW5083 is one of the most common because it is very cheap.

We can find it in the form of laminated or sawn plates.