Ergal 7075 lega alluminio-zinco resistente e leggera

Alloy 7075 is mainly made of aluminium and zinc, and it stands out for its good mechanical resistance (the best among all aluminium alloys). Generally, binary alloys Al-Zn are not used because Al-Zn-Mg alloys are preferred. Zinc increases resistance and hardness and eases the auto-quenching of the alloy itself.

Alloy 7075 is mainly made of aluminium and zinc, and it stands out for its good mechanical resistance (the best among all aluminium alloys). Generally, binary alloys Al-Zn are not used because Al-Zn-Mg alloys are preferred. Zinc increases resistance and hardness and eases the auto-quenching of the alloy itself.

Al-Mg-Zn alloys, which are thermically treated, have the highest traction resistance. In welded structures, these alloys may compete with some types of steel.

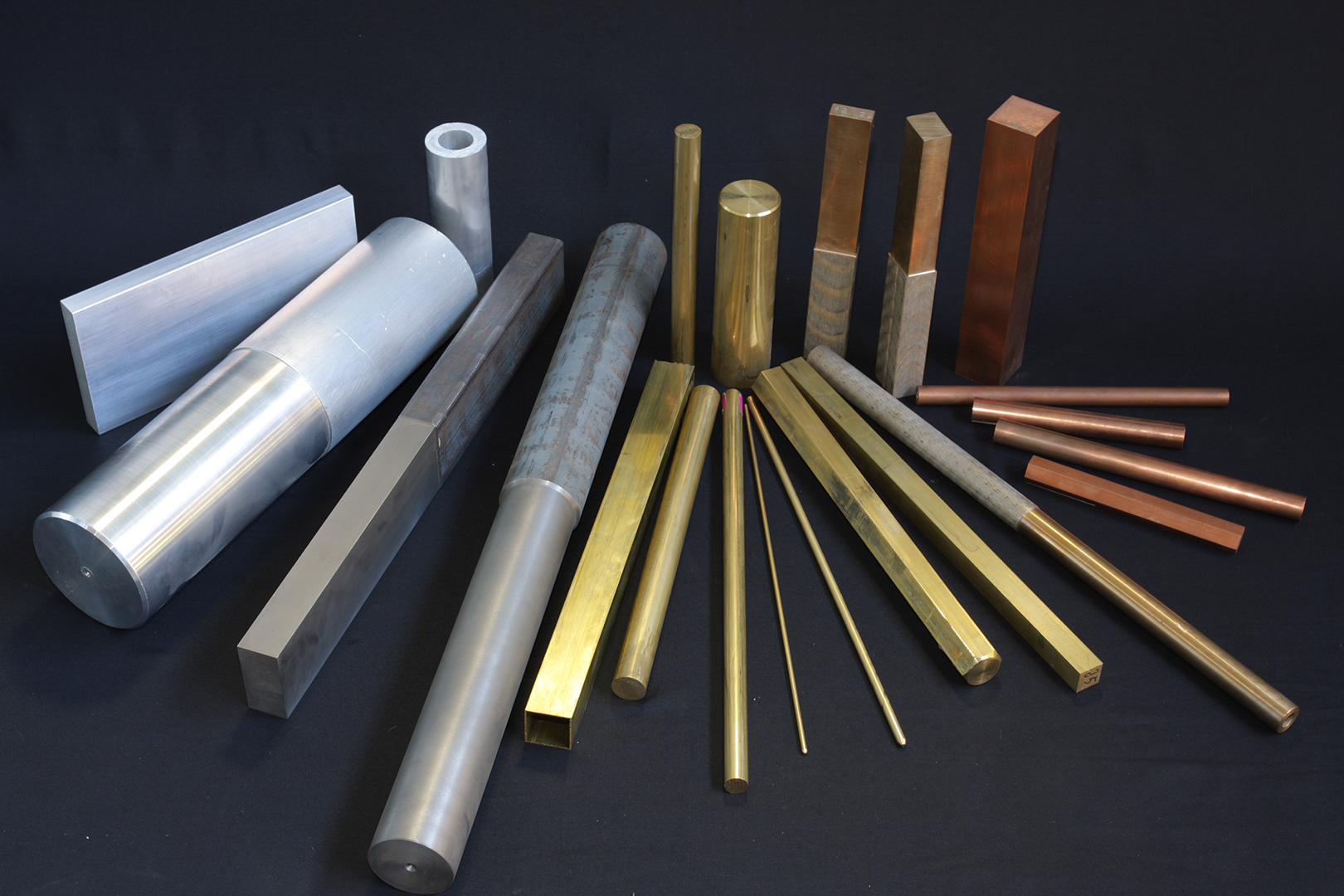

Ergal, or Ergal 55, is available in a wide range of round bars and plates. It is used in many fields, such as aeronautic field, motorcycle and transport industry, and in any highly stressed part.

Technical characteristics of EN AW7075

- High mechanical resistance

- Good weldability and corrosion resistance

- Very good machinability: tiny shavings and excellent finishing

- Acceptable for anodizing

Physical characteristics of EN AW7075

- Density 2,81 g/cm3 at 20°C

- Thermal conductivity at 20°C: 155 W/m °C (at T0)

- Tensile strength: 71100 Nnm2

Ergal is mostly used to produce highly stressed parts and components.

Musola Metalli S.p.a. can supply aluminium EN AW7075 in round bars and plates.

You can contact us to ask for availability or a quotation.